At first blush, the city of Palo Alto and the business of snow clearing don’t appear to have much in common. The California center is located in the heart of famed Silicon Valley, where temperatures rarely dip below the freezing mark and snow is even more rare.

Palo Alto is home to Teleo, a technology solutions company that has created an AI-powered system that allows virtually any make or model of machinery to be operated remotely or autonomously.

The Teleo Supervised Autonomy system was launched four years ago with a focus on the construction and mining industries. It has since been adopted by several other industries including pulp and paper milling, logging, munition clearing, port logistics and agriculture. The company recently expanded into the snow clearing business and has already signed up two major U.S.-based clients: ALFF Construction in Arkansas and Storm Equipment in Minnesota.

Vice-president of sales Mark Piotto says the inspiration to adapt the company’s system for snow clearing was a chance meeting between Teleo staff and Storm representatives at CONEXPO in Las Vegas a few years ago.

Storm manufactures snow clearing equipment and is one of the largest commercial snow and ice removal companies in southern Minnesota. Like many companies these days, it has struggled at times to hire enough staff to keep up with the demand for its services and wanted to know if Teleo would be willing to work with them to come up with a solution.

After conducting some preliminary snow clearing tests at various locations last winter, the Teleo system will be employed full-time this winter by both ALFF and Storm in a variety of settings including multiple big box retailers. Piotto says the early feedback Teleo has received about the use of its system for snow clearing has been overwhelmingly positive.

“The customers really feel that the control station is comfortable, the response time is immediate and the sensory input is exactly what they need,” he said.

Teleo’s system is “brand agnostic” meaning it can be retrofitted on any type of machine regardless of who the manufacturer is. For example, ALFF is using it on a John Deere 333G compact track loader this winter while Storm is using it with a 332G wheeled skid steer from John Deere.

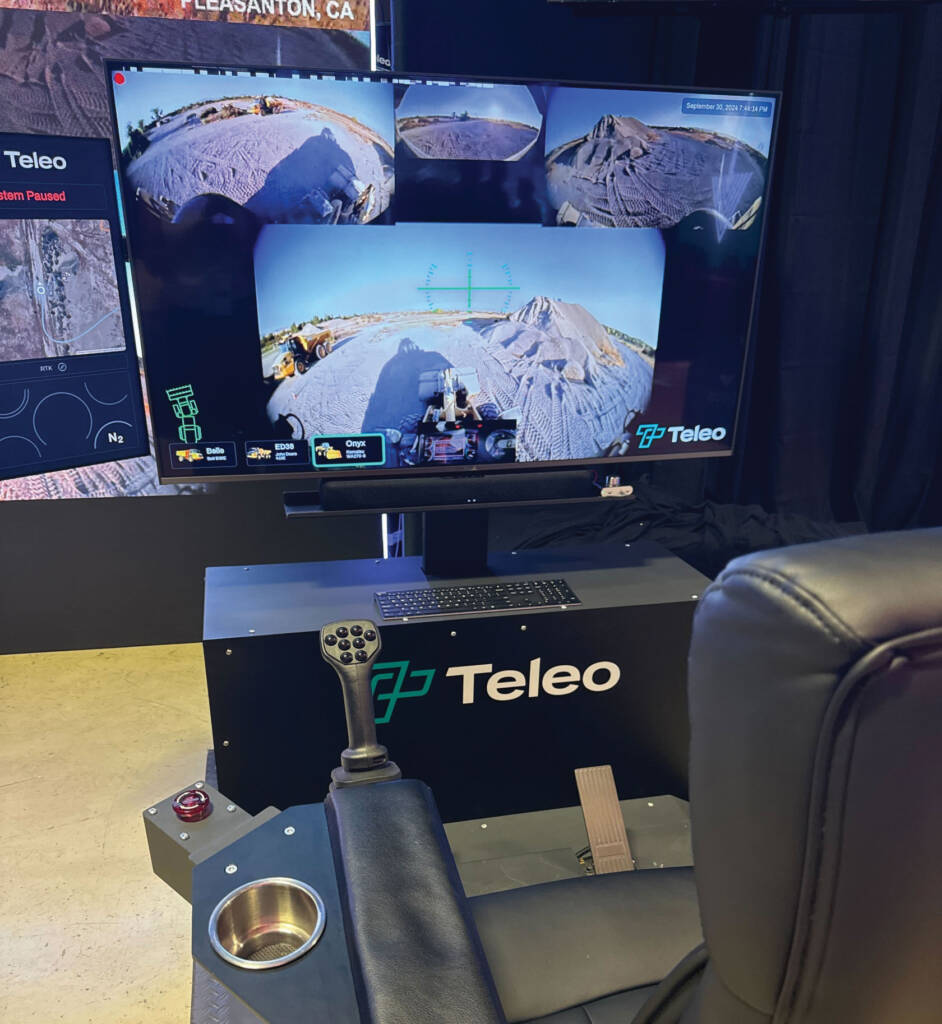

The Teleo Supervised Autonomy system features a control center that includes multiple high-definition monitors, two joysticks to control whatever piece of equipment it’s plugged into, audio from the machine that is being controlled and haptic feedback (vibration) in the operator’s chair to simulate what they would feed if they were in the cab of the machine. “That sensory input is extremely important for the operator experience,” Piotto said.

The beauty of the system, according to Piotto, is the fact that there isn’t a huge learning curve for operators. “The learning experience has been unbelievably quick. It’s really intuitive,” he said. “Operators with no experience have really enjoyed it and operators with experience have been extremely excited about the comfort of it.”

The view the operator has from their control station is designed to replicate what they would see from the cab of the machine down to the most exact detail. The monitors provide them with the precise GPS location of the machine along with cycle times, fuel usage and diagnostics for the device being controlled. A series of four to seven high-definition cameras attached at different locations offer a 360-degree view of the outside of the machine. “The visibility is better than if you were sitting in a skid steer or in a loader. In fact, we can even see underneath the bucket of a loader,” said Piotto.

Teleo tested the system on a number of machines in Finland last winter and it passed with flying colors. Piotto says he has no doubts it will do likewise in North America’s harsh winter conditions.

“Performing in [bad] weather is not a challenge,” he said. “They actually performed a test [in Finland] where they videoed the view from the office to the machine and you could barely see the machine. But when you looked at the view from our control station facing the same direction, we had better visibility than if you were to look [from] that machine with your own naked eye.”

Teleo’s system is designed so that operators can easily toggle back and forth between its remote control and autonomous functions. For example, a machine may be operating autonomously, but will ask the operator for assistance if there’s a problem such as when a machine’s snow clearing blade becomes full or the machine requires assistance with pushing a snow pile.

The system is also capable of recording the path an operator used to clear snow from an area. Once it’s been recorded, the operator can use the autonomous function the next time to duplicate the exact same path. Piotto says one of the biggest advantages of the system is that it allows companies to multiply their workforce since operators can operate multiple machines simultaneously when the autonomous function is in use.

It also allows them to deploy operators more effectively. As soon as an operator completes one job they can start another almost immediately since they don’t have to drive several miles to get from one jobsite to the next. “It’s literally the click of a button and you are a thousand kilometers or a thousand miles away. It’s that quick,” said Piotto.

Teleo’s VP of sales acknowledges the company did encounter some challenges in adapting its autonomous technology for snow removal. First was teaching the AI system how the wing under a plow moves snow and how that’s different than picking up material in a bucket and dumping it into a hopper. It also had to be taught how to avoid objects like parked cars, light standards and curbs so they aren’t damaged.

So, how does Teleo’s system compare to conventional snow clearing efforts? Piotto said, “Our customers have told us that it’s going to be as productive as their current solution. And they’re going to be able to respond faster … because they don’t have to send a person to a remote jobsite to clear snow.”

He says he is excited about the system’s potential to expand the pool of talent available to snow clearing companies at a time when many businesses are struggling to attract workers. He says it could help to attract younger workers who are interested in working with technology, but are reluctant to work in remote or uncomfortable environments. It will also allow workers who aren’t physically able to operate conventional snow clearing equipment, such as wounded veterans and disabled people, to do so using remote or autonomous technology.

“That would be a huge win for us because we desperately need people in the industry. My hope is that this technology will attract the next generation of operators,” said Piotto.

Another potential win is the fact that Teleo’s system can help snow clearing firms reduce their carbon footprint. Since there is no operator inside a machine’s cab, no energy is required to heat its interior, Piotto says. As well, fewer carbon emissions are generated since operators don’t have to drive back and forth between multiple locations during a shift.

Although it’s early days, Piotto is confident that demand for his company’s technology is going to be great. “The demand is already ramping up. People are asking about it every day. There’s a demand because the labor shortage is real and the struggle to clean parking lots is real. There’s no stopping where it could go. There’s really nothing stopping us other than a customer [not]wanting to partner with us.”

![[image placeholder]](https://www.snowopsmag.com/wp-content/uploads/2023/09/placeholder@2x-890x664.png)